TIMELESS, MODERN, AESTHETIC

Where Touch Meets Aesthetics.

TAN GROUP

Tan Group started fabric production in 1995 and has become a fully integrated facility with Yarn Dyeing, Towel and Knitted Fabric Dyeing, Digital Printing, Weaving, and Open Width Dyeing and Finishing departments.

Read MoreOUR COLLECTIONS

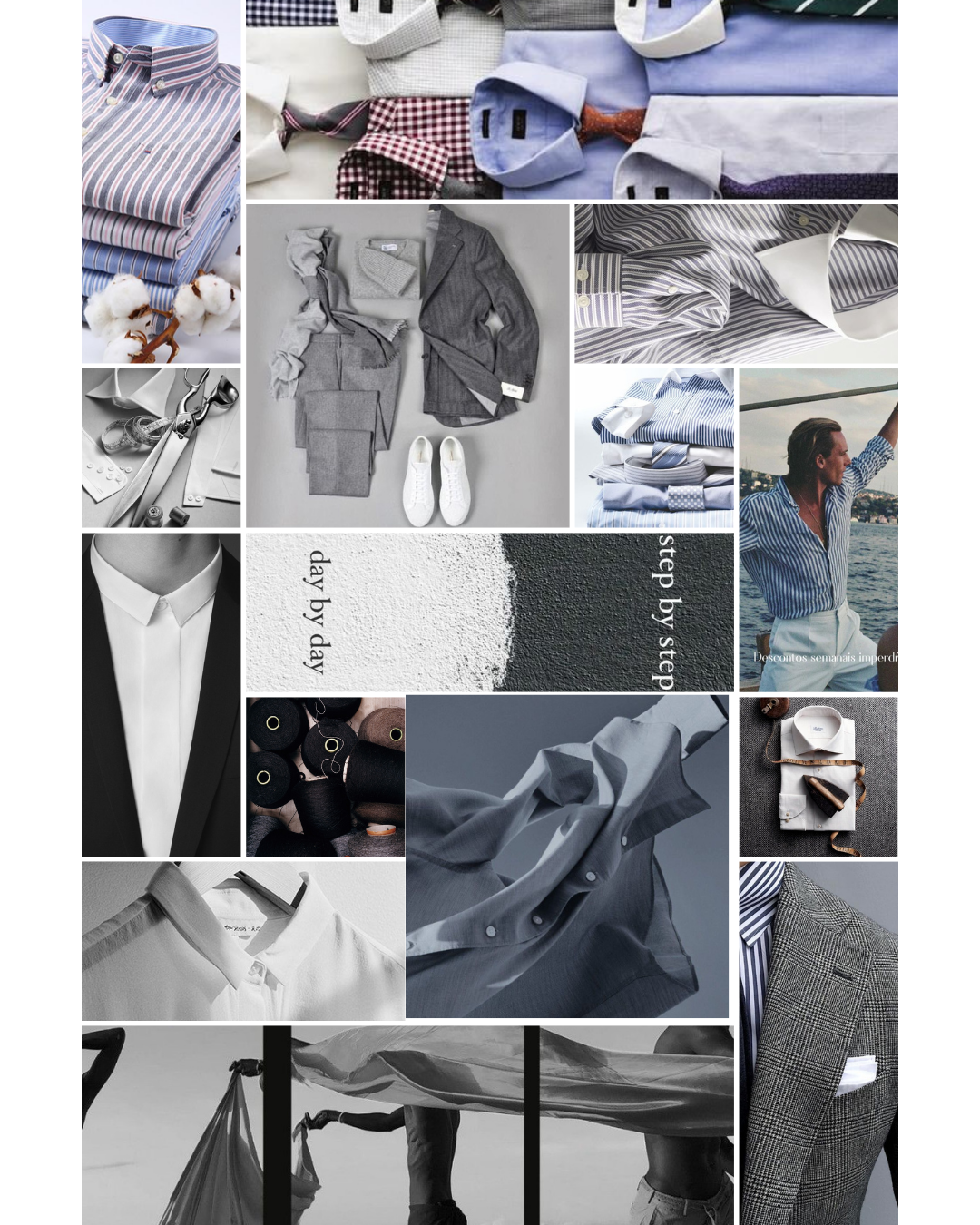

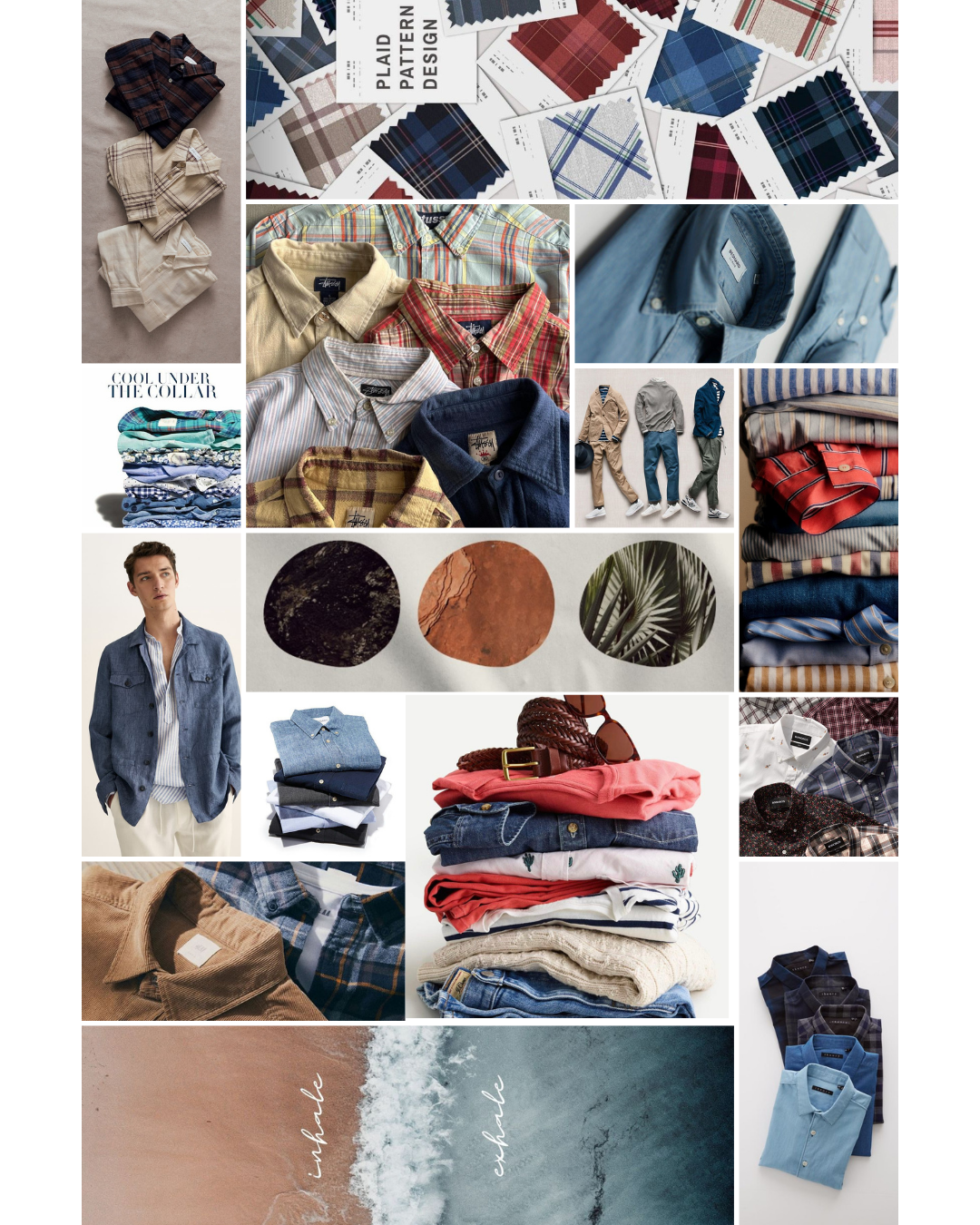

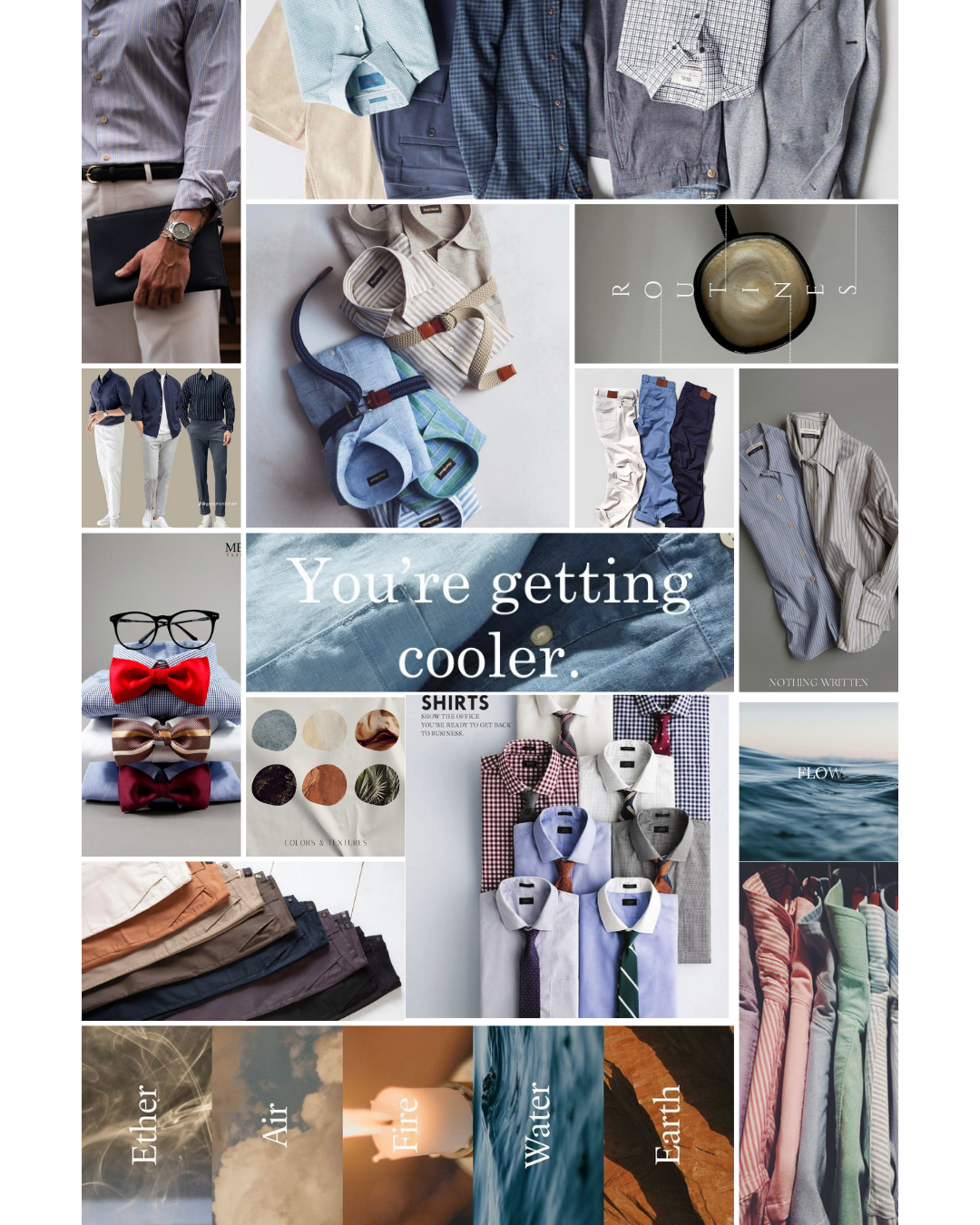

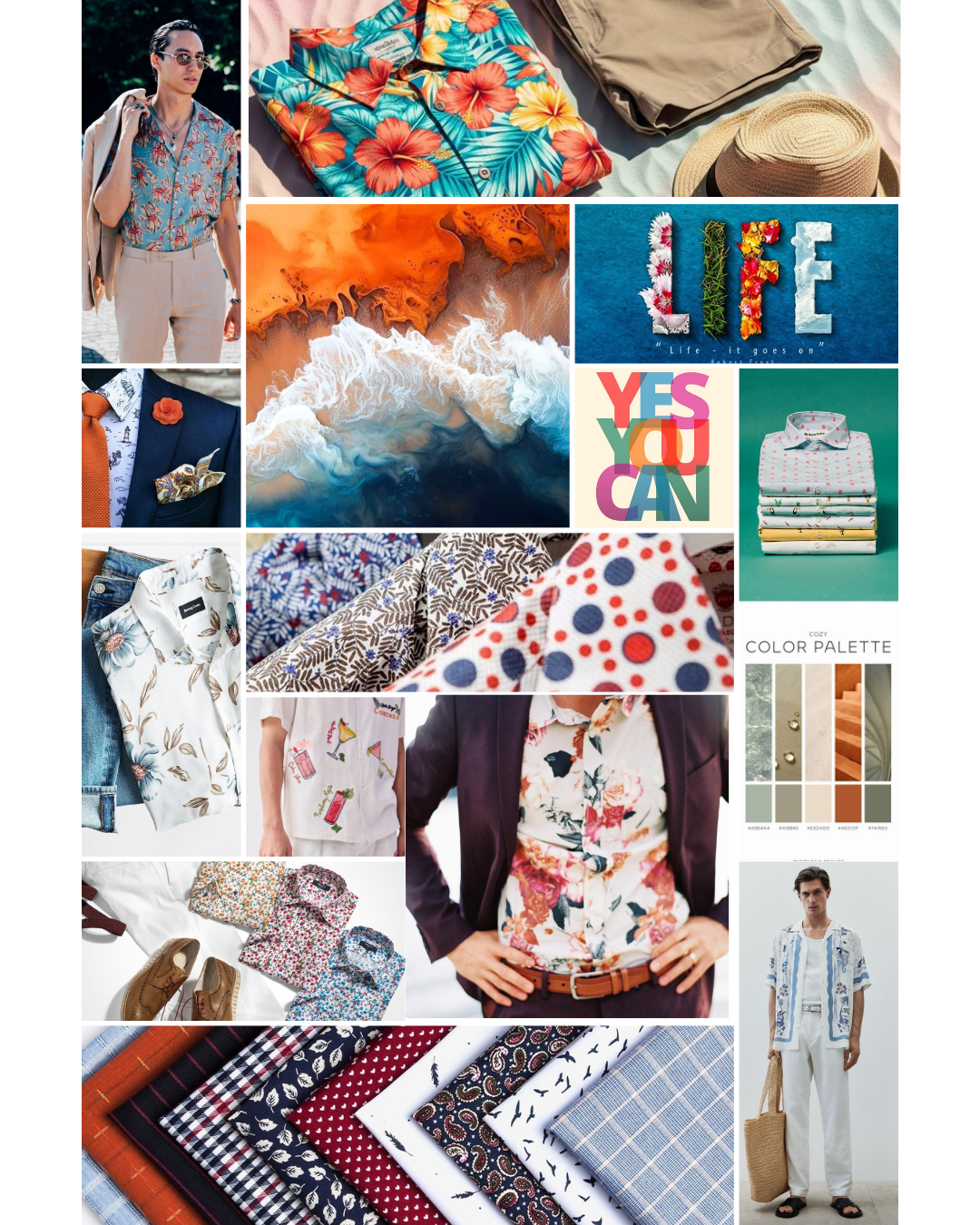

Our new collection was shaped around the dynamism of modern urban life, comfort needs and high quality expectations. Visit our Online Collection for much more

TAN Group in Numbers

We are proud of our growing production capacity and customer portfolio every day.

OUR PRODUCTION DEPARTMENTS

Integrated production in 75,000 m² covered area with 800 employees

Yarn Dyeing

In our high-technology yarn dyeing kettles, we dye yarns in a wide range of counts from 6/1 Ne to 200/2 Ne with reactive and indanthrene dyes. We dye yarns made of different fibers and blends, including 100% cotton, linen, viscose, Tencel™, wool, cashmere and cotton-lycra. Organic yarns used in organic collections are dyed in accordance with GOTS standards, adopting a sustainable and environmentally friendly production approach. Yarn colors to be used in pre-production handloom and sample works are prepared in short lead times, providing fast and flexible service to our customers. The daily production capacity of our yarn dyeing unit is 8,000 kg.

HT Dyeing

With our high-tech HT towel and knitted fabric dyeing machines of different capacities, we perform dyeing and finishing processes mainly for 100% cotton and cotton blend knitted fabrics, as well as 100% polyester, cotton-polyester and cotton-nylon blend fabrics. We provide high quality and process control in towels, bathrobes, voile fabrics and fabric groups requiring free washing and special washing. The daily production capacity of our HT dyeing unit is 32,000 kg.

Weaving

In our weaving department, PICANOL brand rapier weaving looms are used, and we have a monthly production capacity of approximately 800,000 meters with 154 weaving looms. We also have 3 sample warping machines, 4 cone warping machines, 2 automatic drawing-in machines and 2 sizing machines; providing speed, flexibility and quality continuity in sample, collection and serial production processes. Our sample warping capacity is approximately 1,000 samples monthly. Additionally, special and value-added productions are carried out with 4 jacquard weaving looms that provide pattern and design flexibility.

Digital Printing

Digital printing technology continues to transform the design approach in many sectors, especially fashion and textiles. With our creative and dynamic design team that closely follows current trends, we produce both our own digital printing collections and custom printed patterns for our customers at high quality standards. With 4 MS JP7 & 1 MS JPK digital printing machines and 2 Arioli steaming machines in our facility, we have a monthly production capacity of approximately 400,000 meters of digitally printed fabric.

Finishing

In line with increasing quality expectations in the textile market, as Tan Tekstil, we apply finishing processes specific to the intended use of fabrics and customer demands with our high-tech and continuously renewed machinery park. While regularly updating our technology investments in line with changing living standards and current expectations, we support our expert and qualified team with continuous training; positioning innovative ideas at the center of our production processes. In this approach, we perform high quality special finishing applications such as Aero, Peach, Brush, Easy to Iron, Easy Care, Top Easy Care, Nano Care, Silky, Soft, Antibacterial, Antiviral, Anti-Odor, Mechanic Stretch, Water Repellent and UV Filter. The daily production capacity of our finishing plant is 50,000 meters.

Fabric Inspection

In line with our production approach that focuses on customer satisfaction, our quality control unit meticulously inspects all production processes. In order to provide the highest quality standards to our customers in the fastest way, in addition to internal controls carried out in our production units, fabrics are examined in detail by our expert quality control team and shipped after approval. Our quality control processes are carried out with modern control machines supported by artificial intelligence integration; ensuring error-free, sustainable and consistent quality assurance.

OUR AGENCIES

ITALY - CI-ELLE SRL

ITALY - CI-ELLE SRL

FRANCE - ROBRACKS

FRANCE - ROBRACKS

SPAIN - J. EZCURRA REPRESENTACIONES S.L.

SPAIN - J. EZCURRA REPRESENTACIONES S.L.

BELGIUM - PLANET TEXTILE

BELGIUM - PLANET TEXTILE

USA - STUDIO AD

USA - STUDIO AD

CANADA - HALLOWELL AGENCY

CANADA - HALLOWELL AGENCY

JAPAN - KEI CORPORATION

JAPAN - KEI CORPORATION

SOUTH KOREA - MARINE FABRON

SOUTH KOREA - MARINE FABRON

QUALITY POLICY

At Tan Group, we consider quality not just as a production standard, but as a fundamental value that guides all our processes. At every stage from yarn to fabric, we operate with the principles of meticulousness, continuity and full compliance with international standards.

Read MoreINNOVATION

At Tan Group, innovation is not just about producing something new; it is about continuously advancing quality, efficiency and design. By closely following changing market dynamics and global trends, we continuously improve our production processes and collections.

Read MoreENVIRONMENTAL AWARENESS

At Tan Group, we commit to managing waste from production processes with Zero Waste awareness. Our goal is to ensure disposal, reduction, reuse, recycling and recovery of waste without harming the environment and human health; thus reducing natural resource usage and operating this cycle in a healthy way.

Read MoreDiscover Our Fairs

Current information about national and international textile fairs we participate in.

QUALITY CERTIFICATES

Our quality and environmental certificates at international standards